Japan’s New Gundam Factory Lets You Design Your Own Model Kit

Japanese pop culture news edited by Patrick Macias

Bandai’s BHC PDII Museum lets visitors design and produce custom plastic models based on the Gundam anime series

Hands-on exhibits teach modeling, coloring, mold design, and packaging

Visitors can take home their personalized model data and printed packaging

Bandai Spirits is opening a new kind of attraction in Shizuoka, Japan: a hands-on museum where visitors design and create their own plastic models. The BHC PDII Museum, located inside Bandai’s new production hub, opens to the public on September 2. In a preview tour on August 20, guests got an early look at what could inspire a whole new generation of builders.

The museum is reservation-only and tickets are distributed by lottery three months in advance. Entry costs 2,860 yen (approx. $18.50) for adults (13+), 1,100 yen (approx. $7.10) for children aged 6–12, and is free for preschoolers. A limited number of first-come tickets are available if lottery spots remain unfilled.

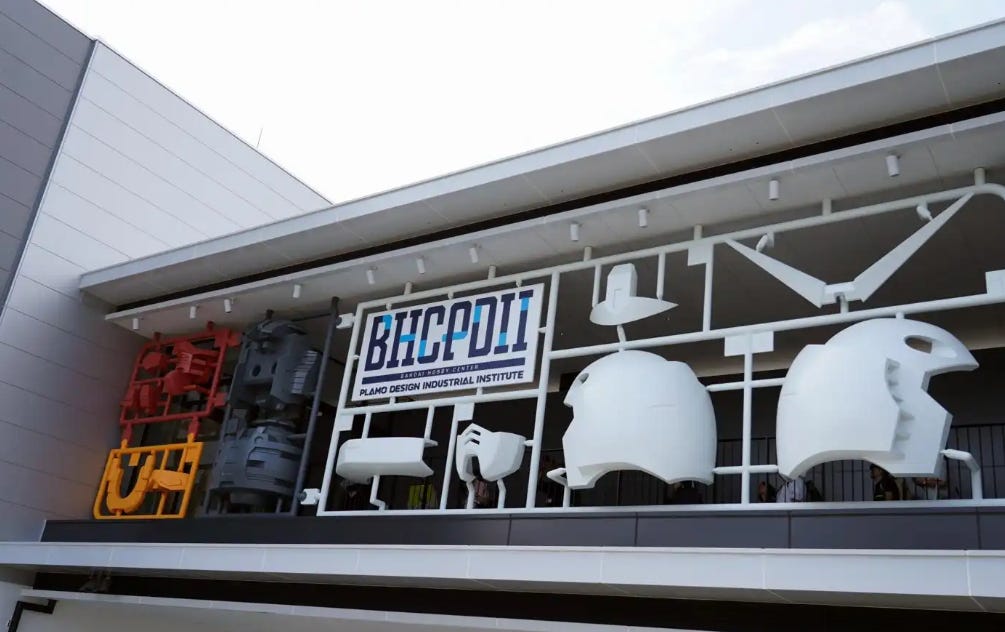

Giant Gundam Head at the Entrance Shows Scale of the Experience

The first stop is the “Monument Entrance,” where guests are greeted by a 1:1 scale model runner from the MG 1/100 RX-78-2 Gundam Ver2.0 kit. This huge replica shows the unassembled head part of Gundam, just as it appears on a plastic model frame. Visitors can walk behind it and closely inspect the shape and structure of the parts.

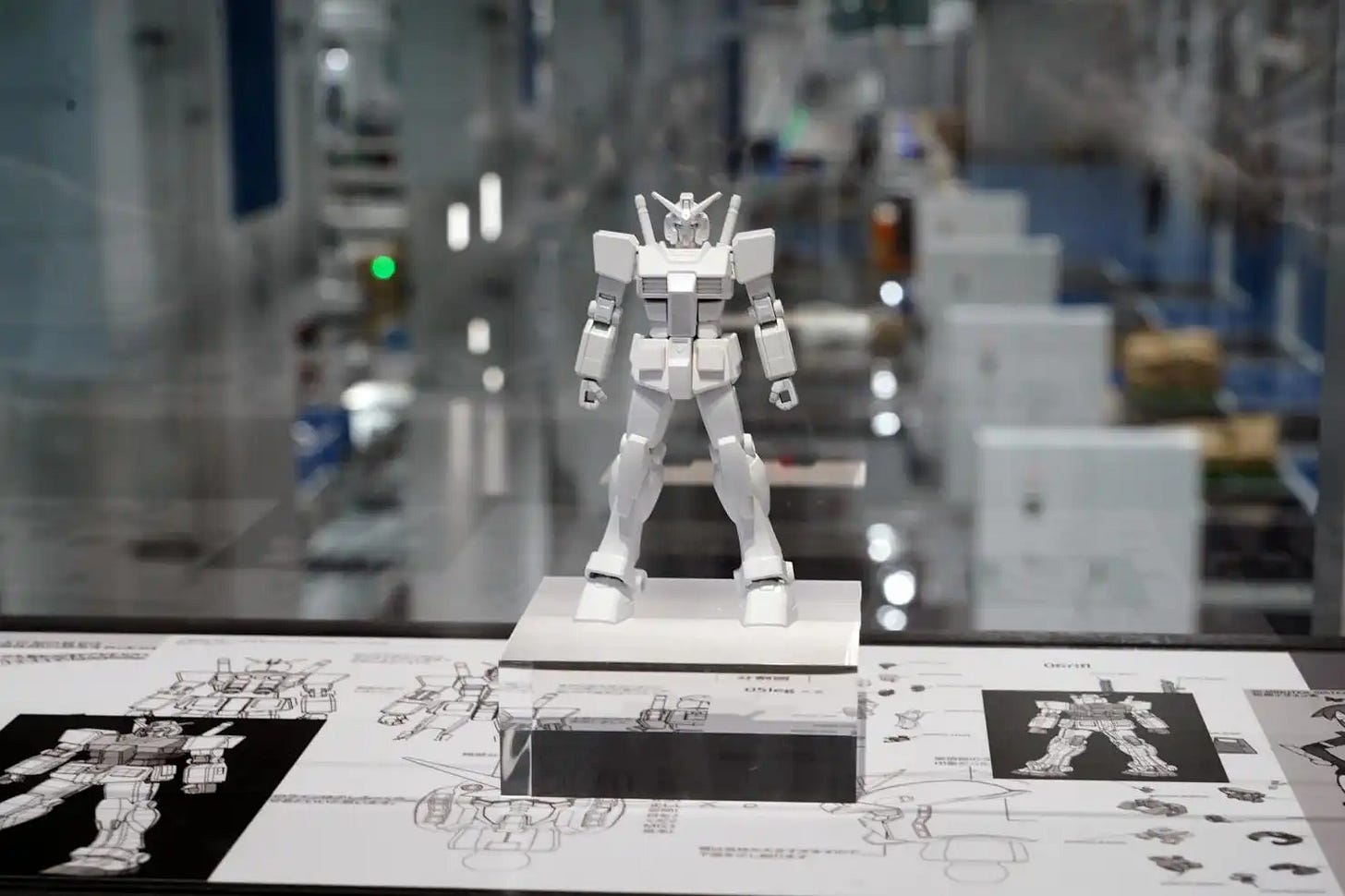

Inside the entrance hall, injection molding machines and metal molds are on display, leading to the “Study Area.” This section features a full “Design Road” showing real planning sheets, explanations of manufacturing processes, and an impressive wall of 4,000 completed Gunpla kits. This number visually represents the daily output of Bandai’s multi-color injection machines.

Learn How Gunpla Are Made From the Inside Out

In the “Study Area,” visitors learn how plastic models are developed, designed, and mass-produced. Exhibits explain how Bandai’s innovations have shaped model production over the years. You can also explore how product planning begins and how molds are crafted for high-efficiency production.

The 4,000-Gundam display is a powerful demonstration of the factory’s output. Each model represents a runner created in a single day—showcasing the industrial scale behind your favorite kits.

Hands-On Creation Zone Lets You Customize Your Own Model

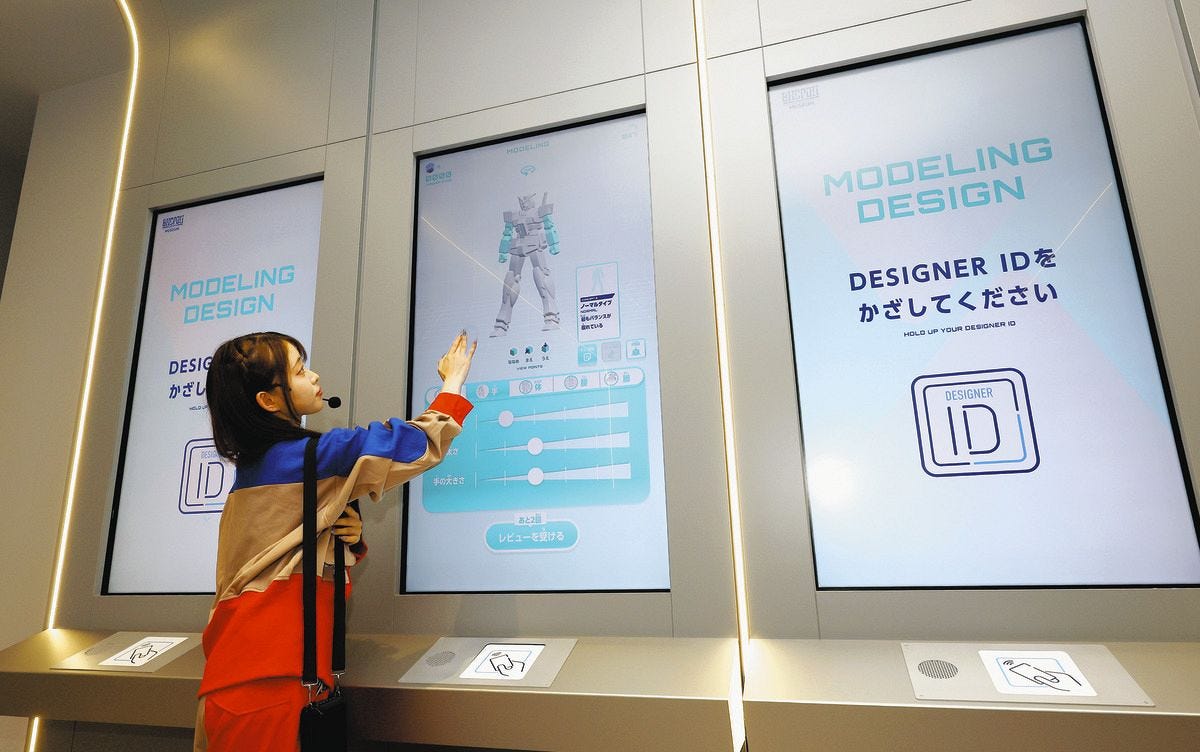

The “Laboratory Area” is where the real fun begins. Here, visitors use touchscreen terminals to simulate every step of the production process: choosing a base model (Gundam, dinosaur, or bishoujo character), adjusting part sizes, selecting colors, designing the runner layout, and even making the final packaging.

Each design choice is rated, allowing guests to aim for efficiency or go wild with creativity. Whether you thicken the limbs for a bulkier Gundam or go off-model entirely, it’s all part of the experience. All choices are saved to a special ID card, and a printed package sticker can be taken home.

Tweak Color, Form, Mold, and Package Just Like a Real Designer

The “Coloring” stage allows you to set up to five custom colors. Next, in “Runner Design,” you determine the optimal mold layout for resin injection. Learning how to place each part to minimize production time gives a deeper understanding of how real kits are engineered.

During the “Injection Molding” segment, guests observe a real machine at work and receive a fresh runner as a souvenir. Finally, the “Package Design” stage lets you customize a label with pose, logo, and background, then print it out as a sticker to complete your personal kit.

More Than a Factory Tour: A Glimpse Into Creative Production

The BHC PDII Museum aims to go beyond the usual factory tour. It encourages hands-on engagement and invites visitors to experience not just how models are made, but how they’re conceptualized from the start. The team hopes it inspires curiosity about product planning, engineering, and design.

Although you can’t physically enter the working areas of the factory, many rooms have glass walls that give you a peek at real-time production. This forward-thinking facility blends education and entertainment, aiming to spark creativity and potentially train the next generation of model designers.